Pp Stationery Sheet Extrusion Line Suppliers – ABS HIPS PC PMMA Multi-layers sheet and board extrusion line – Leader

Pp Stationery Sheet Extrusion Line Suppliers – ABS HIPS PC PMMA Multi-layers sheet and board extrusion line – Leader Detail:

Extruded sheets advantages and main applications

Home appliance field: The extruded ABS HIPS boards are mainly used for vacuum forming purpose, featured with impact-resistance, corrosion resistance, widely used for home appliance field, such as internal bladder, drawer, door plates for the refrigerators, out shell for washing machine and air conditioner, water dispenser etc.

Sanitary ware field: The extruded ABS PMMA boards are mainly used for vacuum forming purpose. It retains the features of acrylic surface rigidity and gloss, and also has the advantages of ABS impact resistance, widely used for the sanitary are boards, such as bathtub board, shower room, sauna room, washing tank board etc.

Baggage field: The extruded ABS PC boards are mainly used for vacuum forming purpose, widely used for the travelling cases fields, such as trolley cases, luggage, leisure bags, middle and high class rigid shell of travelling cases, recreation bags, etc.

Advertising field: guiding board, machinery sign, advertising decoration, indoor decoration and etc.

Automotive field: it is mainly used for producing top covers of cars and buses, instrument boards, backrest, car doors, window frames, shells of the motorcycles, electrical vehicles, benchbark sheets, golf vehicles etc.

Features of this extrusion line

1) Advanced screw and barrel structure design can realize the raw material good plasticization and stable pressure and reliable extrusion. Hard screw and barrel, special structure design of screw is suitable for PP/PE material, 100% recycled material possible. The single screw extruder can be designed as vacuum degassing type or without based on clients’ requirements.

2) Gravimetric dosing system for raw material handling is available, which can realize proportionally precise mixing of several types of raw materials components.

3) The three roller calendars can adopt horizontal type, oblique type, vertical type or other angles type designs to meet different types of sheets extrusion. The driving system of the roller calendars can be common reduced motor control or servo motors control.

4) Finally discharging stacker adopts automatic manipulator with mechanical arms and also designed with the overturn function, greatly reduced the labor cost.

5) Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

Main technical data

| Main extruder model | LSJ-120 | LSJ-150 | LSJ-160 |

| Co-extruder model | LSJ-45, LSJ-65, , LSJ-75, LSJ-90 | ||

| Suitable material | ABS, HIPS, PMMA, PC | ||

| Product width | 1300-1600mm | 1800mm-2000mm | 2000-2500mm |

| Product thickness | 1-6mm, up to 8mm | ||

| Product structure | Mono layer, ABA, AB, A/B/C, A/B/C/B/A, A/B/C/D/E co-extrusion | ||

| Max capacity | 300-400kg/h | 400-550kg/h | 600-1000kg/h |

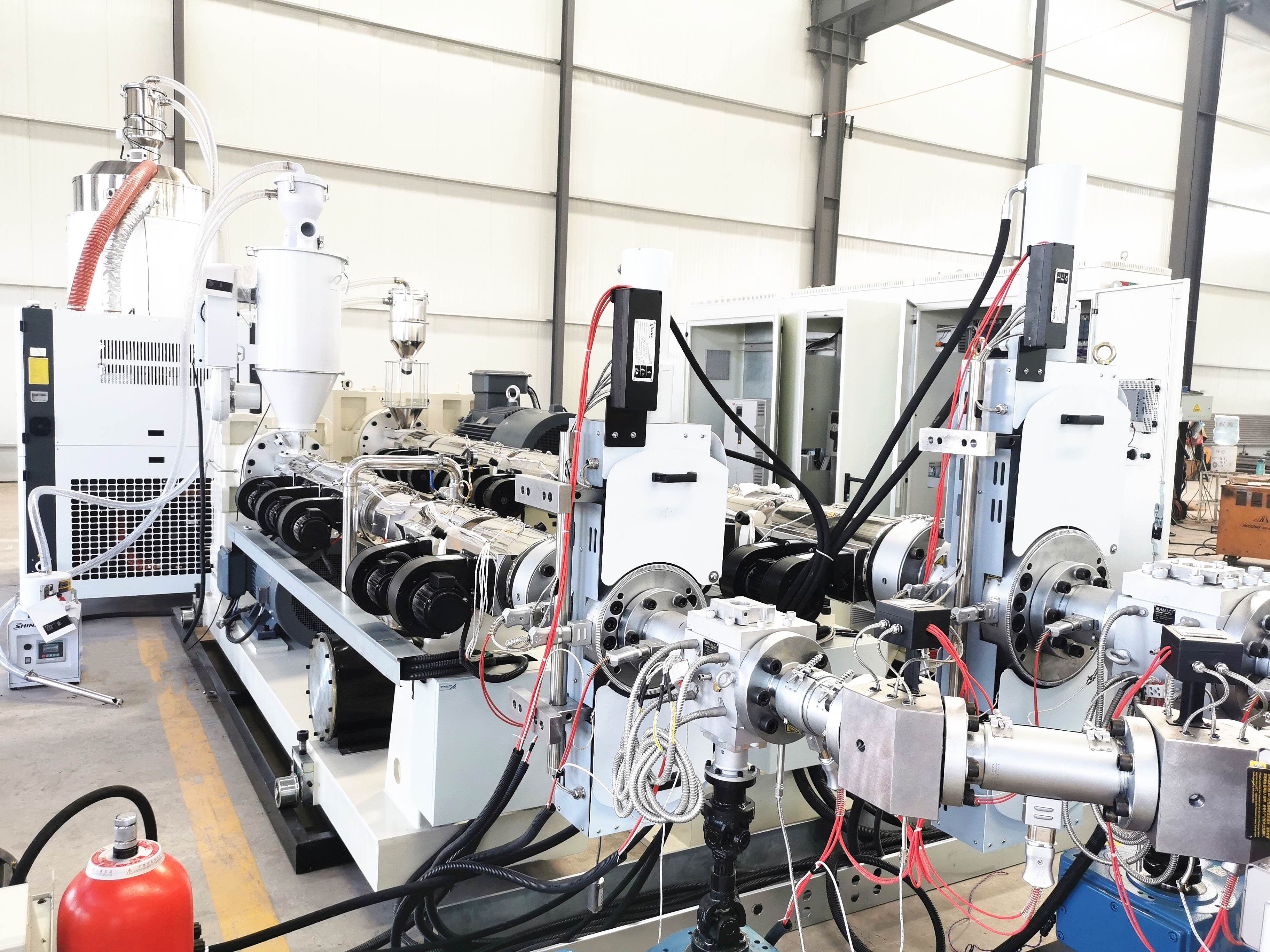

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Pp Stationery Sheet Extrusion Line Suppliers – ABS HIPS PC PMMA Multi-layers sheet and board extrusion line – Leader , The product will supply to all over the world, such as: Guyana, Sao Paulo, Greek, Create Values,Serving Customer! is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.