China Pmma Sheet Extrusion Line Manufacturer – PC Solid Compact Sheet/Embossed Sheets/Corrugated Sheets extrusion line – Leader

China Pmma Sheet Extrusion Line Manufacturer – PC Solid Compact Sheet/Embossed Sheets/Corrugated Sheets extrusion line – Leader Detail:

Main features of the line

1) Dehumidifying and drying system for to reduce the moisture of the raw material

2) Gravimetric dosing system for raw material handling is available.

3) Advanced screw and barrel structure design can realize the raw material good plasticization and stable pressure and reliable extrusion

4) By changing roller calendars, the line can produce both high gloss smooth finish sheet and also matte finish sheets and other textured sheets as customized.

5) Advanced technology optimized the extrusion process and result in an excellent and stable products.

6) High flexibility of our lines, suitable for manufacturing a wide range of raw material and products types.

7) Complete automation of the extrusion line saved the labor cost and reduced the maintenance and processing cost as well.

8) Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

Applications for the sheets

PC general purpose solid sheets have high impact strength and are also high temperature resistant. Both have special co-extruded ultra violet (UV) protection. Virtually unbreakable, and yet as transparent as glass with less than half its weight, Compact Sheets are easy to fabricate as well as to install. Known for their excellent insulation properties, these sheets are suitable for cutting, drilling, bending and thermoforming as well. They are widely used for architecture glazing, window shield, interior decoration, sound barrier, advertisement and signage, security & protection, Industrial manufacturing etc.

PC embossed sheets have several features with high impact resistance, light weight, can be easy cold bend processed and hot molding. Hence, it can be widely used in construction and decorations, in glazing & lighting, canopy roofing, bathroom, partition & shelters, interior designing etc.

PC solid corrugated sheets have an outstanding roofing material that offers superior physical properties, which features with excellent weather resistance, high light transmission, light weight, widely used for roofing of warehouses, workshop, or other simple construction buildings etc,

Main technical data

| Model | LMSB120 | LMSB130 |

| Suitable material | PC | PC |

| Product width | 800-1220mm | 2100mm |

| Product thickness | 1-6-12mm | 1-6-12mm |

| Max capacity | 400-500kg/h | 550-650kg/h |

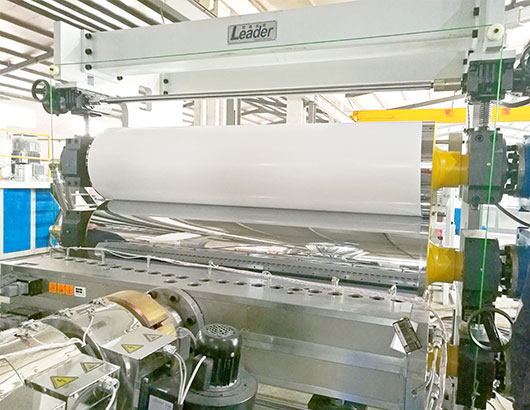

Product detail pictures:

Related Product Guide:

It adheres for the tenet Honest, industrious, enterprising, innovative to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for China Pmma Sheet Extrusion Line Manufacturer – PC Solid Compact Sheet/Embossed Sheets/Corrugated Sheets extrusion line – Leader , The product will supply to all over the world, such as: Iraq, Liverpool, Kuwait, Our company will continue to adhere to the superior quality, reputable, the user first principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!