China Hdpe Waterproof Sheet Extrusion Line Manufacturers – PE Geomembrane Waterproof Sheet Extrusion line – Leader

China Hdpe Waterproof Sheet Extrusion Line Manufacturers – PE Geomembrane Waterproof Sheet Extrusion line – Leader Detail:

Main features of the line

1)Gravimetric dosing system for raw material handling

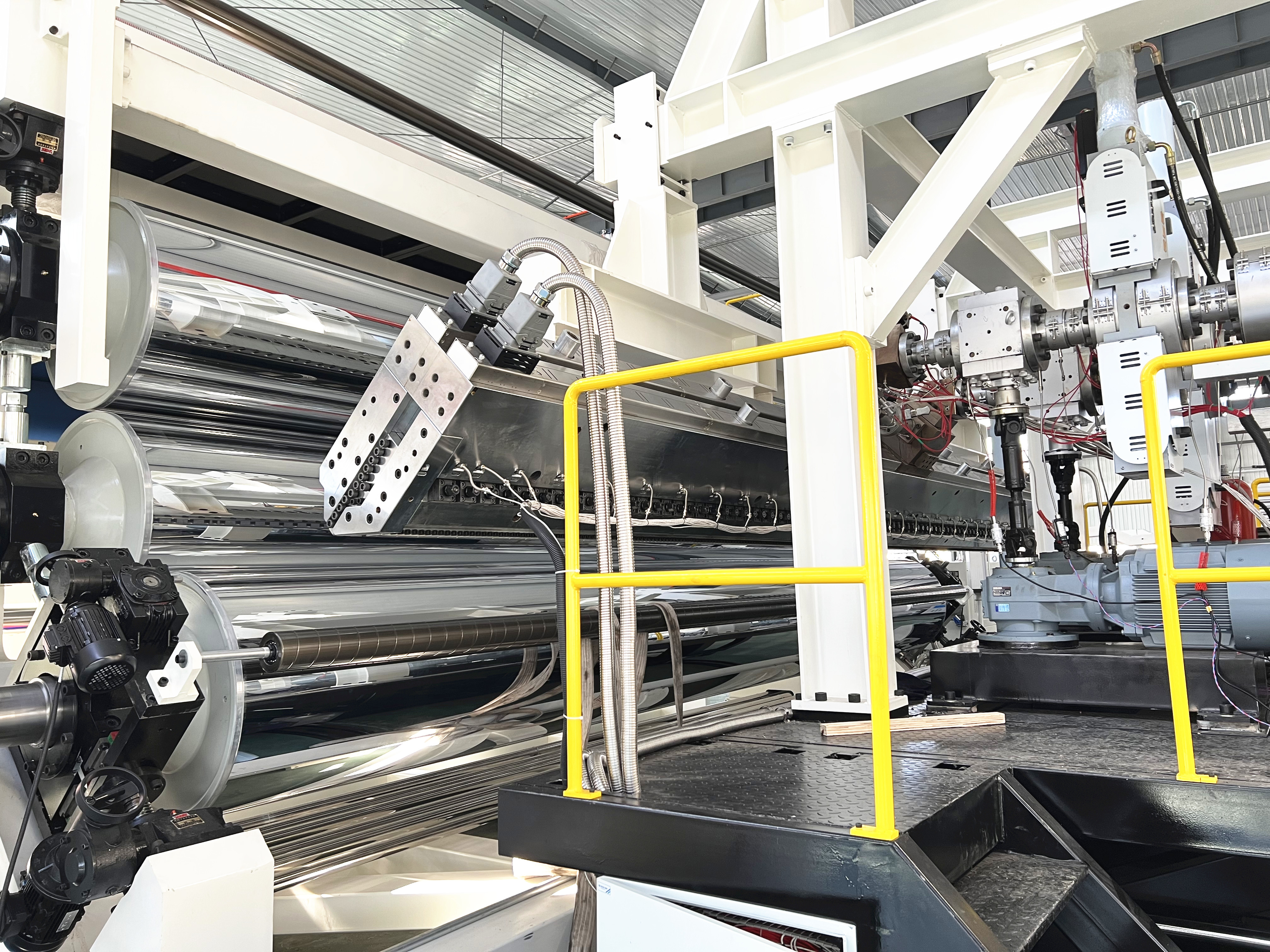

2)High capacity extruders with movable frame

3)Two or three sets of extruders are equipped, can realize the mono layer and also multi-layers co-extrusion

4)Automatic T die and online thickness scanner is optional

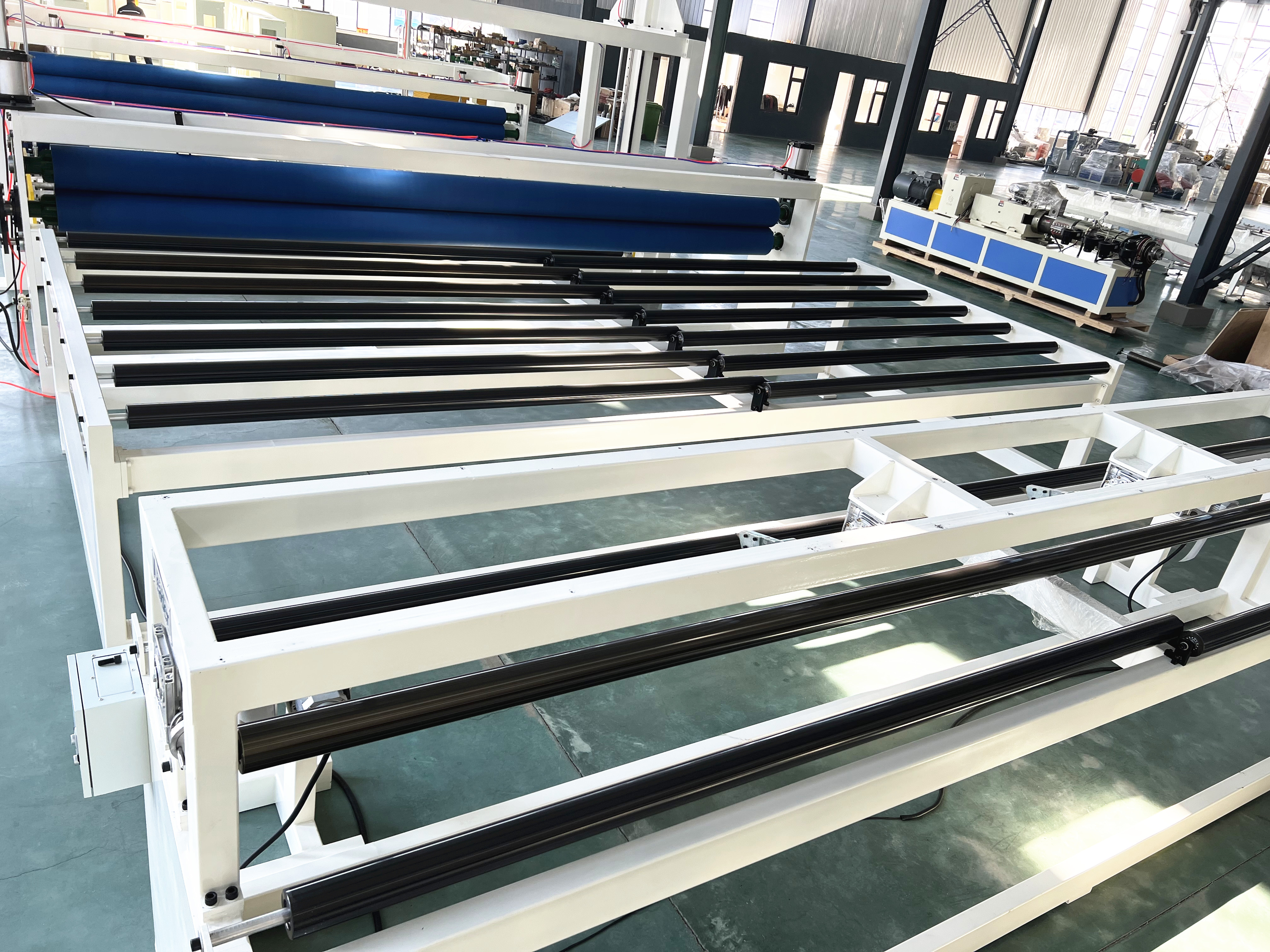

5)Exclusive roller calendars and traction structure for maximum flatness & consistent thickness of membranes

6)Both mirror roller calendars and embossing roller calendars are available and replaceable.

7)Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

| Model | LMSB120, LMSB150 | LMSB150/150, LMSB160/160 |

| Suitable material | PE | PE |

| Product width | 1000-4000mm | 5000-8000mm |

| Product thickness | 0.5-3mm | 0.8-3mm |

| Max extrusion capacity | 600-700kg/h | 1200-1500kg/h |

Remark: The specifications are subject to change without prior notice.

Specifications of the geommebrane

Sheet size: width 1000-8000mm, thickness 0.5-0.7-0.8-3mm

Sheet structure: mono layer or multi-layers co-extrusion

Sheets surface: smooth/plain type, textured type, composite geotextile coating type

Processing raw material

PE granules, recycled flakes, carbon black or masterbatch, other filler material etc,

Main applications of the geomembrane

1) waterproofing usage in industrial & civil buildings, including the green roof, flat roof, and the sloping roof.

2) Underground waterproof: reservoir, dam, pool, swimming pool,

3) Waterproof usage in tunnel drainage, grain depot, artificial engineering, landfill, artificial lake, foundation moisture-proof

Product detail pictures:

Related Product Guide:

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We're seeking forward in your check out for joint development for China Hdpe Waterproof Sheet Extrusion Line Manufacturers – PE Geomembrane Waterproof Sheet Extrusion line – Leader , The product will supply to all over the world, such as: Orlando, Melbourne, Belgium, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

A good manufacturers, we have cooperated twice, good quality and good service attitude.